"We’re doing everything we can to make the best product possible, and that includes trying new technologies and processes that we haven’t used in past product development."

Summary

- WHOOP prides itself on adopting new technologies to build new technology. They subject new products to rigorous testing to engineer and manufacture high-quality wearable devices.

- In a head-to-head GR&R between Lumafield and a traditional “$700,000 competitor” performed by WHOOP engineers, the results were within 0.03mm, giving the company the confidence to adopt Lumafield’s technology.

- When travel was restricted during COVID, Lumafield’s cloud platform allowed WHOOP to collaborate efficiently with manufacturers on the other side of the globe as the brand launched a new product.

- Given limited lab space in Boston, a CT scanner that can easily fit into an office environment is a game-changer: various engineering teams can regularly access and use its tools to gain new insights that drive innovation.

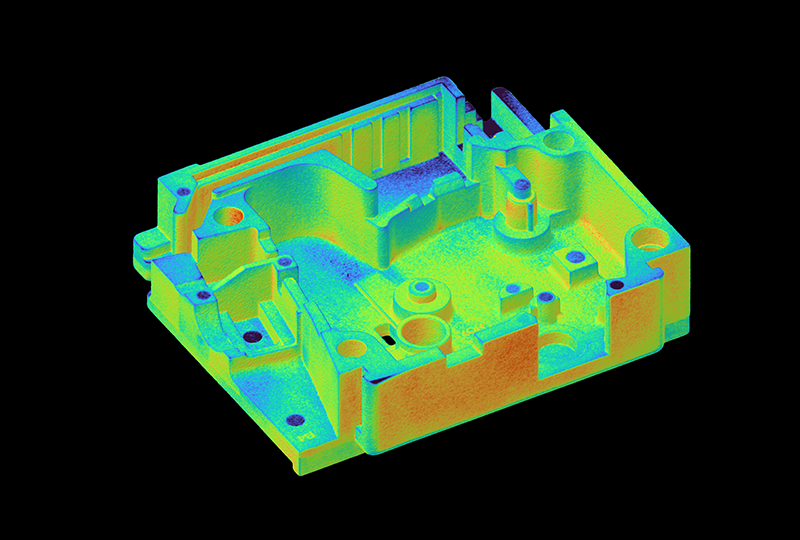

- CT scanning helped WHOOP transition from launch to mass production, enabling engineers to see new details and ensuring high-quality products for its users.

Background

WHOOP is pioneering cutting-edge technology to optimize human performance. The company’s membership platform uses fitness and health-tracking wearables and proprietary algorithms to create a sophisticated portrait of a member’s physiology, generating bespoke feedback to enhance the user’s performance, whether on the field, in the classroom, or a conference room.

In the competitive fitness-tracking space, WHOOP stands out for its fearlessness when it comes to finding new ways to ensure quality. “We’re doing everything we can to make the best product possible, and that includes trying new technologies and processes that we haven’t used in past product development,” explains Aurelian Nicolae, Co-Founder and Chief Hardware Engineer, WHOOP.

WHOOP + Lumafield

The thing that makes us most happy about our partnership with Lumafield is the Lumafield team’s willingness to work with us to try new things.

Anahis Kechejian

Mechanical Engineer

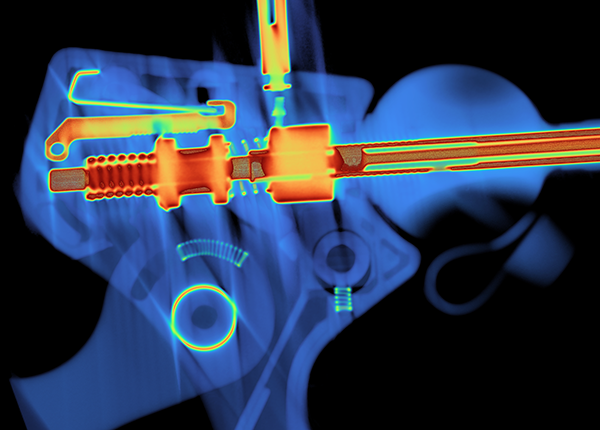

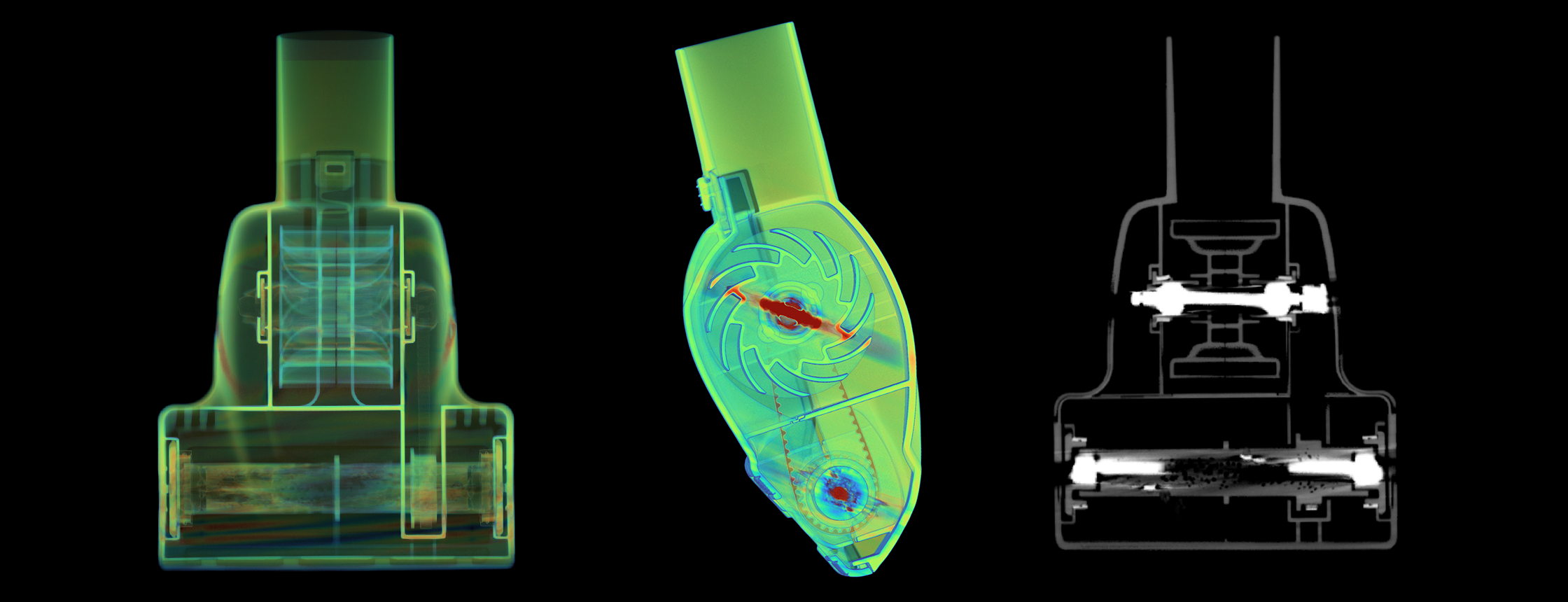

WHOOP is thoughtful when it comes to developing new technology, ensuring that any new tool they adopt is high-quality. To test Lumafield’s accuracy, WHOOP engineers performed a head-to-head gage repeatability and reproducibility (GR&R) between a Lumafield CT scanner and a traditional “$700,000 competitor” scanner. In a GR&R, multiple users take multiple measurements on samples from both systems, looking for repeatability and reproducibility. The results of the two scans were within 0.03mm, giving WHOOP the confidence to go with Lumafield.

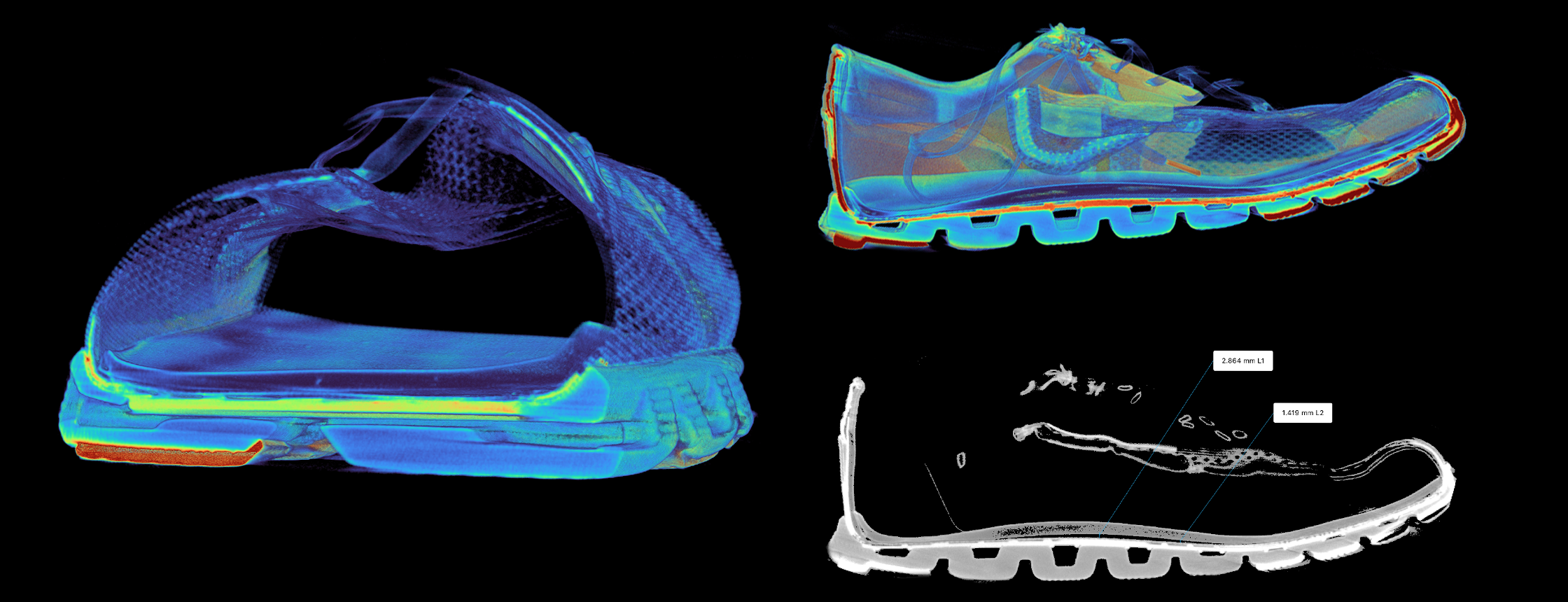

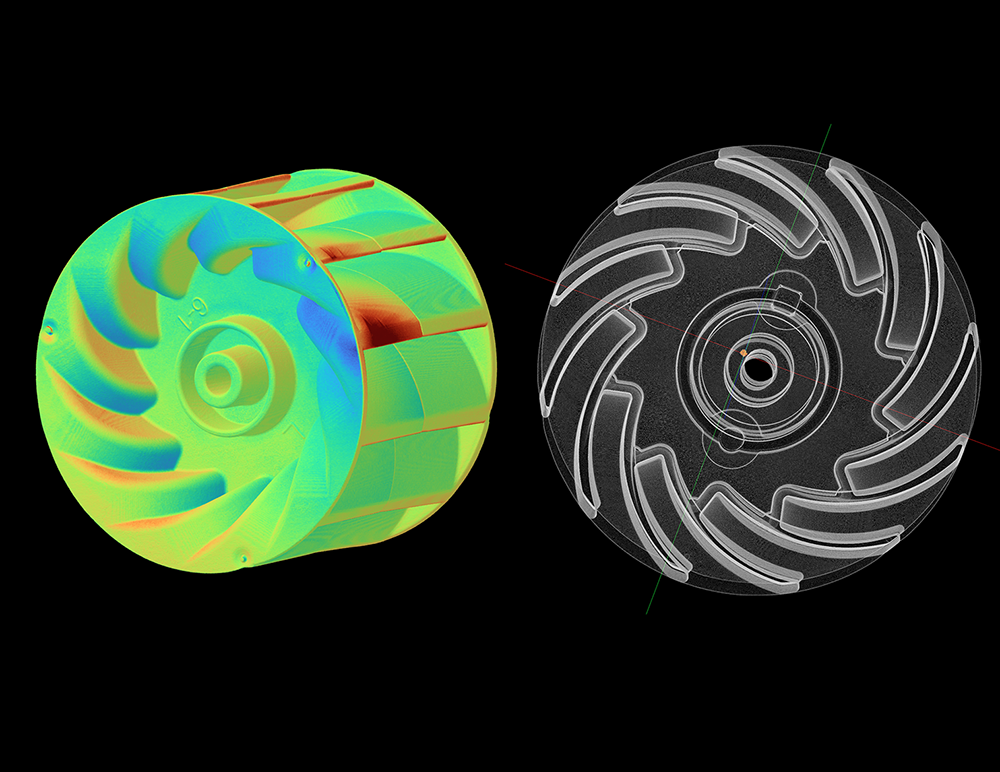

CT scanning has helped WHOOP maintain high-quality hardware while managing new logistics challenges – launching a product into a world reshaped by COVID-19. Travel restrictions posed a particular challenge given the Boston-based company’s collaboration with suppliers around the globe. “There was a time when we were unable to visit a manufacturer, and we needed to find alternative quality control solutions,” said Jake Rutsein, Mechanical Engineer. Having a Lumafield scanner on-site in Boston “made it possible for us to quickly gain insights into our production and provide the right feedback to our partners around the world.”

Accessible Scanners

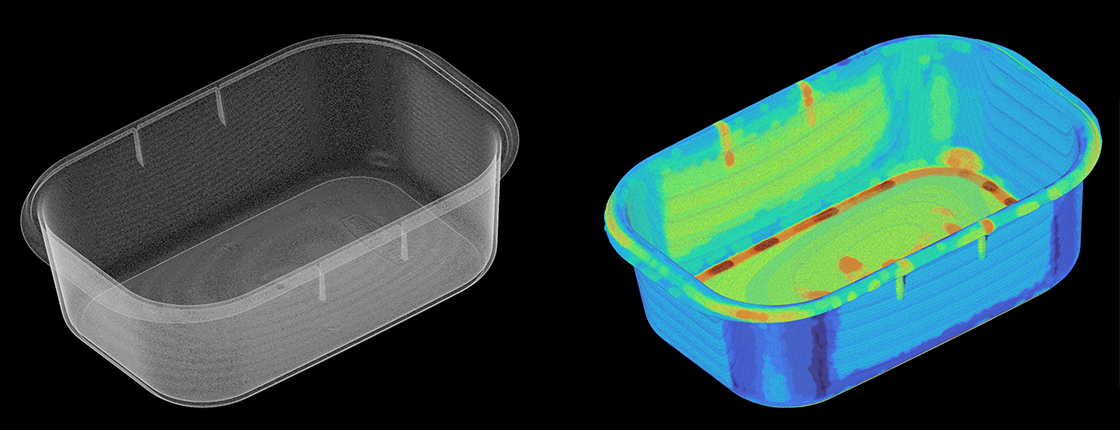

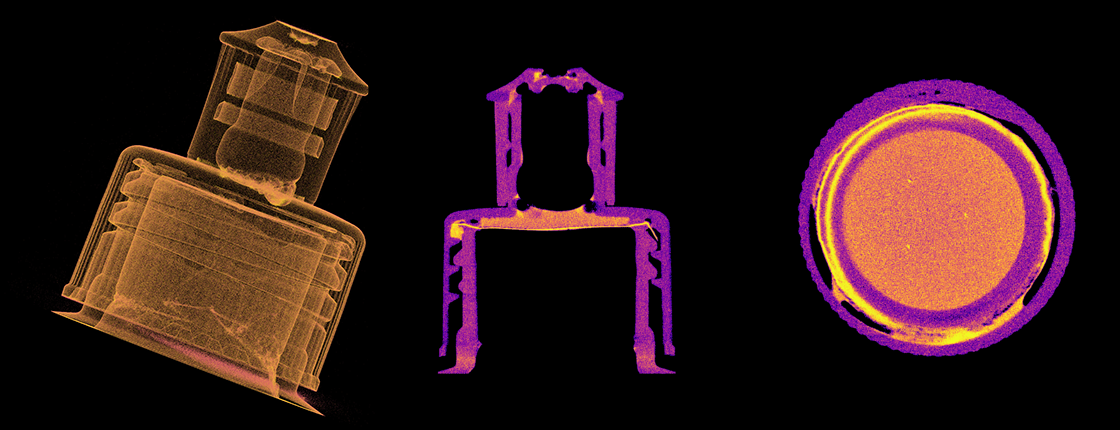

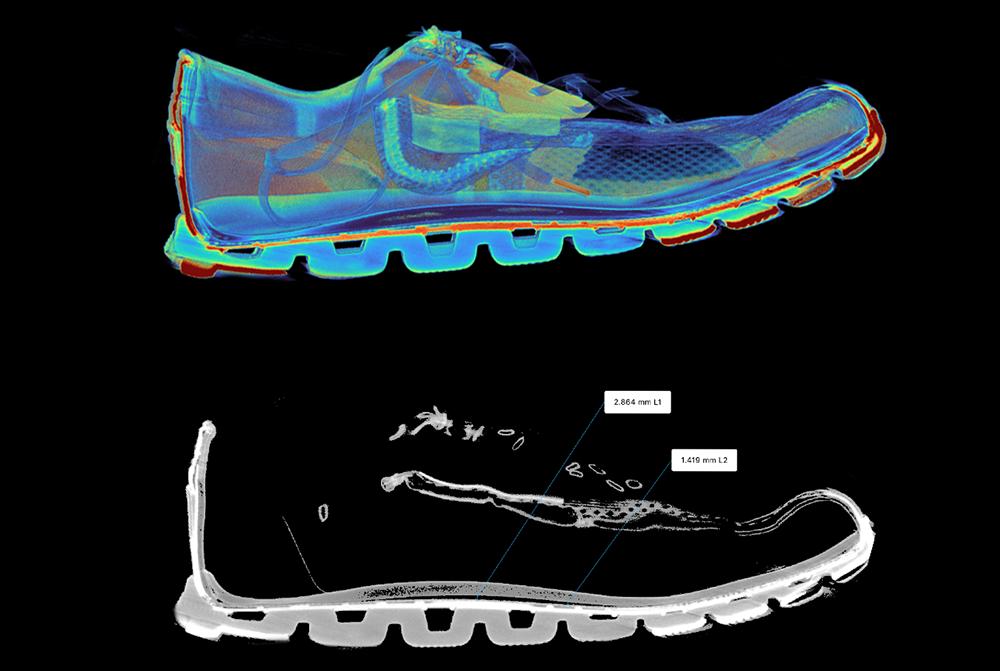

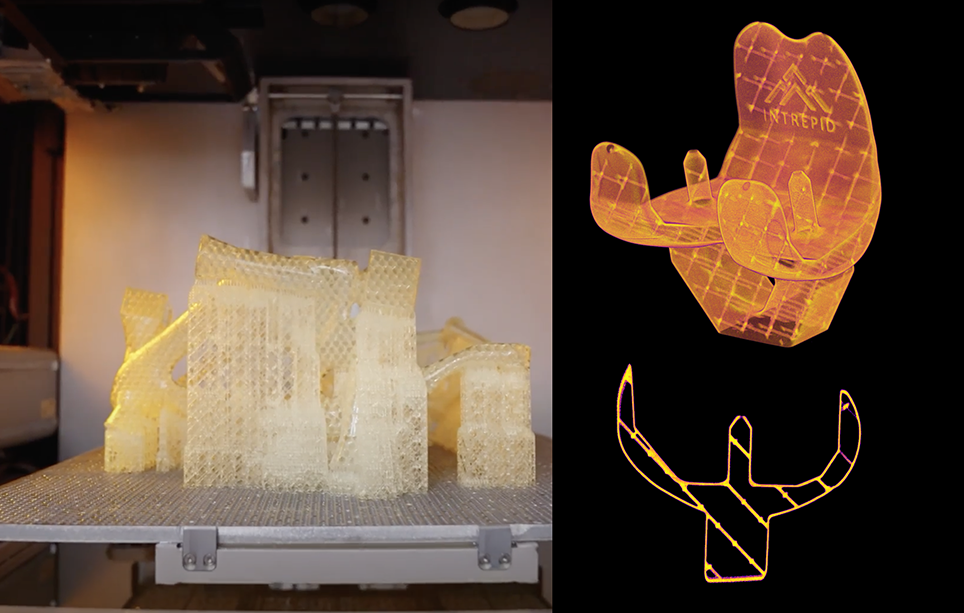

Lumafield’s CT scanner sits in the WHOOP home office, within reach of engineers from several teams. Lab space in Boston is limited. Having a scanner on site—instead of in an out-of-sight lab—allows the engineering teams at WHOOP to benefit from this new tool, from electrical engineers doing inspections of batteries and circuits to mechanical teams working on assembly inspections.

Anahis Kechejian, Mechanical Engineer at WHOOP, explains how CT scanning helped uncover a different view of a section of an early prototype. “We were able to show [a misassembled piece] to our partners and point out improvements before going to production. So they took that information and retrained some of the operators. That was really valuable, finding something that we weren’t looking to find.”

As Kechejian says, CT scanning helps the company “know where we need to put more of our efforts.” Launching a product involves a constant juggling of priorities, and the data Lumafield provides can help order those priorities, giving engineers confidence that they are working on the right things.

“The thing that makes us most happy about our partnership with Lumafield is the Lumafield team’s willingness to work with us to try new things …that collaborative relationship is a huge value add for us,” says Kechejian.